Interior modules

BACKGROUND

Since 2016, SOLUTE has been carrying out assessment projects of the interior of vehicles for manufacturers and OEMs. Using different advanced calculation disciplines (thermal, dynamic, fatigue, optimisation and frequency response), the finishes of components are analysed and proposals are designed with the aim of improving the quality that is perceived by the vehicle's end customer.

In the current market, manufacturers differentiate between premium and basic product lines by noticing an increase in the quality and complexity of the vehicle's interior elements.

The aim of this discipline of Finishes is to be able to insure the stiffness, stability and durability of the elements to provide customer's a sense of high quality. As we move closer to high end products, these require a larger number of tests and requirements that are studied for each part in order to obtain a premium finish.

RESULTS

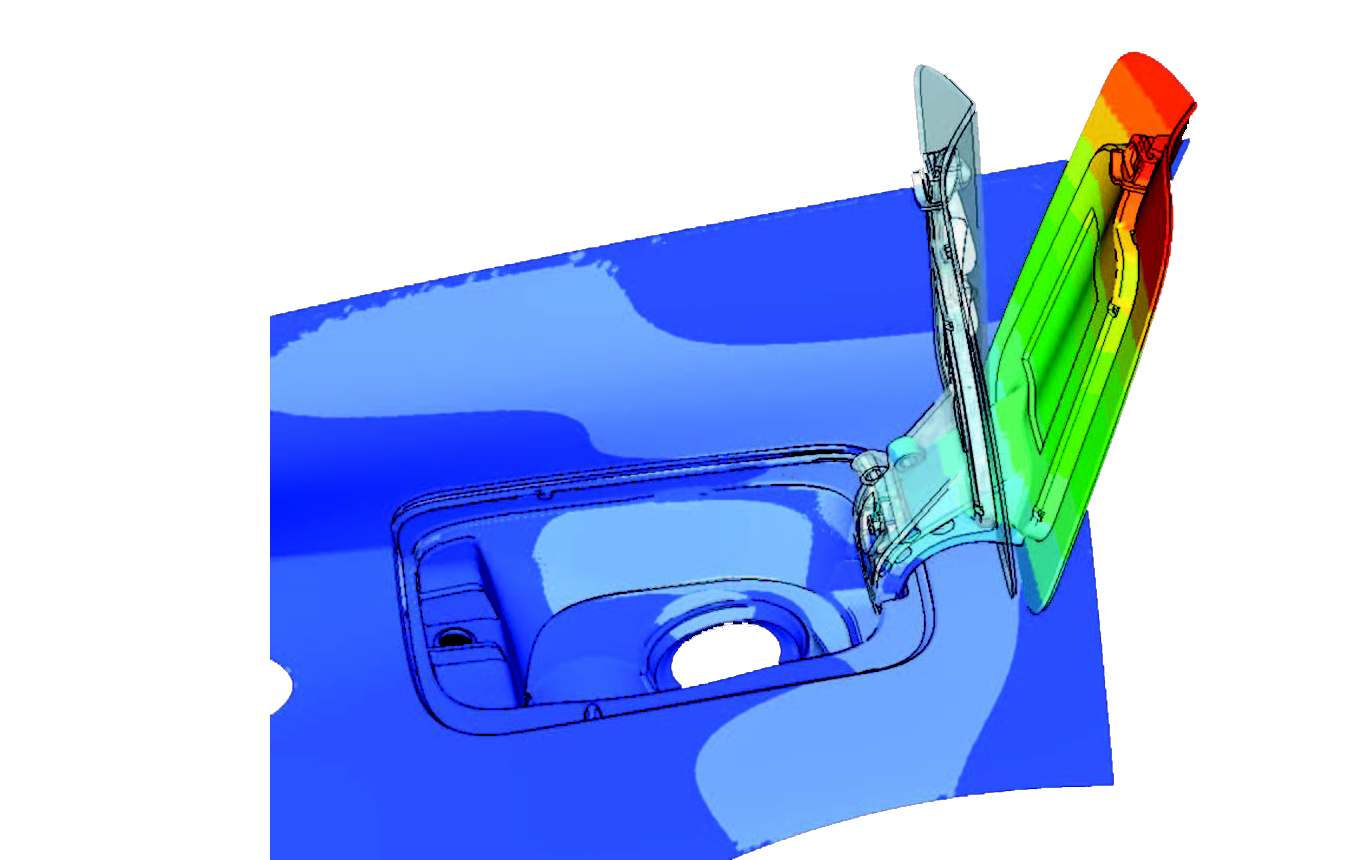

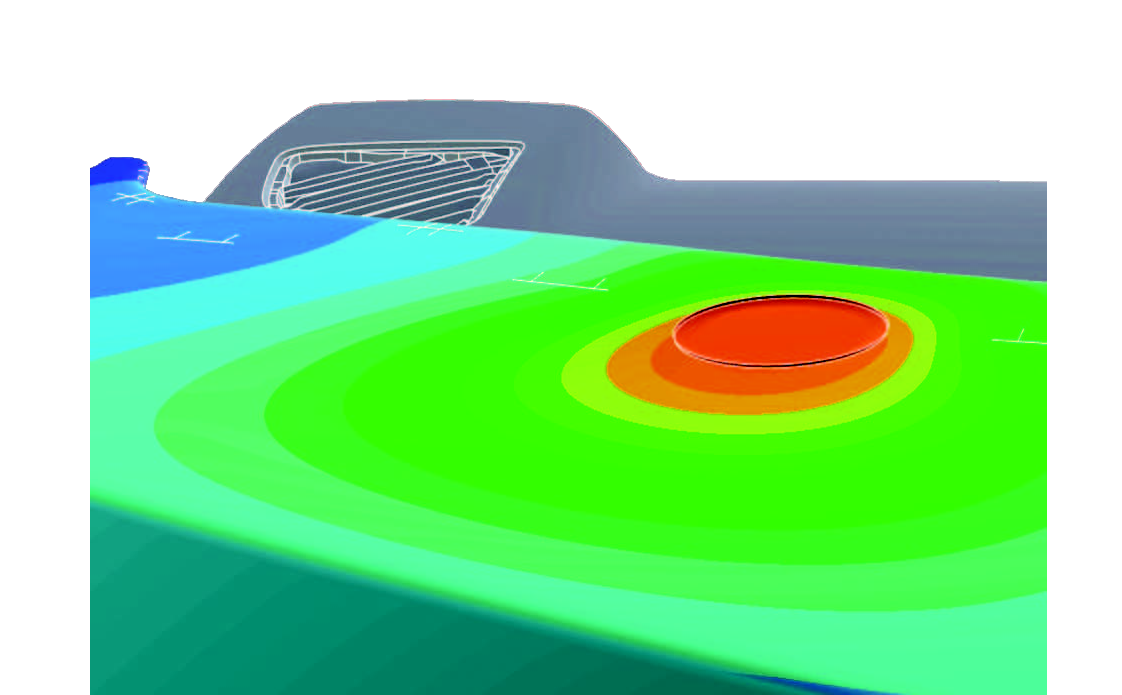

The overall results of these analyses are design proposals that are compliant with the required quality standards and the financial goals of the project. These proposals are delivered to the customer in the form of comprehensive analyses reports, including graphic content of the results of the structural calculations, justifying the improvements with respect to the original models.

EXPERIENCE

Since the year 2016, SOLUTE has been involved in simulating the interior finishes of vehicles for different customers, which include large vehicle manufacturers and suppliers.

The work is focused on the interior of vehicles, from the dashboard to the centre console, as well as the door panels, pillar trim and the entire boot assembly and the petrol cap. In other words, the focus is basically on practically all the plastic elements that are located inside the car.

With the input being the preliminary designs prior to the validation, SOLUTE transforms each system into advanced calculation models and determines the boundary conditions and different types of unions between all the parts.

METHODOLOGY

In coordination with the manufacturer's or parts supplier's technical department, SOLUTE covers the entire process of analysing parts before and after the tests. With the input being the preliminary designs prior to the validation, SOLUTE transforms each system into advanced calculation models and determines the boundary conditions and different types of unions between all the parts. The different analyses (thermal, dynamic, fatigue, optimisation and frequency response) that are carried out by SOLUTE in these types of disciplines are: the stiffness and misuse calculation of the different parts that comprise the model, impact of the head against the dashboard and console in accordance with standard ECE-R21, airbag test, rear crash and modal analysis.

The transformation into calculation models is carried out using standard pre-processing tools that can be found on the market (ANSA, HyperMesh). These detailed models represent all the mechanical properties of the components (thickness, materials) and its specific unions (clips, screws, welds, rivets) which enable to determine their strength individually and as part of an assembly or system.

Once the entire model is mounted with its assemblies and its respective joints, we proceed to calculate the applicable loads using the codes specified by the customer (Pamcrash, ABAQUS, ANSYS and NASTRAN).

Given that, in the first phases of the different projects, in general, the customer's requirements are not entirely met, SOLUTE provides a part that is essential, which is to provide solutions to the problems detected in the analysis of the results. The proposals range from changes to the geometry concepts, to the thickness or materials, optimising the overall behaviour.

As the final phases of the project are completed, physical tests are carried out simultaneously where all the load cases simulated to that point are materialised. Once these tests have been completed, SOLUTE will correlate the models, comparing the test results with the simulation.

This step is of vital importance because we try to ensure the simulation model matches the tests as much as possible; this way, we will have a more complete starting basis for future projects.

For all the analyses, a report is drafted for the customer that includes the results post-processed using specific software (META, HyperView) to adapt the contents of the customer's documentation in compliance with their methodologies and presentation standards.

Wind

Road and access design

A capacity that defines and resolves access for the assembly and maintenance of the different components that constitute a wind farm.

Automotive

HVAC

Capability of guaranteeing a proper heating, ventilation and air conditioning (HVAC) in vehicles used for transport, of both the cabs as well as the compartments where the payload is carried for different reasons, such as conservation or passenger comfort.