Digital Twins

Timeline

2018-2023Sector

VirtualisationScope

Digital twins for operating and monitoring installations.BACKGROUND

The control of business installations and assets can be carried out through the digitisation of these assets by creating a digital twin. After scanning and modelling the installation, data sources are added that enrich the visualisation and facilitate planning the improvement actions or the preparation of simulations that help predict the performance of the assets. SOLUTE generates these models, beginning with the capturing of reality to the collection and treatment of data in real time.

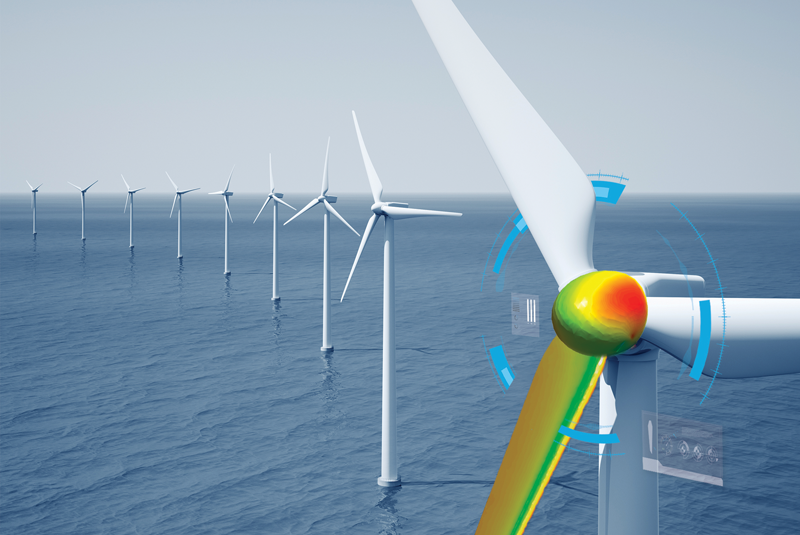

Digital twins are the virtual replica of a model that reflects their real asset with a high degree of accuracy. These replicas incorporate data in real time, collected through sensors, that allows conducting performance studies and implement improvements in the model that can be transferred to the original physical asset they represent.

The handling of this data makes it possible to test different scenarios and different configurations of the product, to observe their response and improve the system's reaction, for the purpose of executing simulations and monitoring the behaviour of the digitised installations.

This technology allows having greater control over the business assets, properly planning the maintenance and improvement strategies as well as reduces the costs associated with these tasks.

RESULTS

Virtualisation and digital twin generation tasks allow monitoring the operation of the digitised installations as well as the planning of change and improvement procedures, with the ability to iterate decisions made at low cost. These tasks also allow monitoring the changes once they have been made, through the visualisation of previous versions of an asset to compare its performance. This helps gain a more thorough understanding of the assets that are present and maintain control over them.

EXPERIENCE

Since 2018 SOLUTE has been collaborating with the managers of industrial installations, such as with the owners and operators of wind parks, hydroelectric and nuclear plants or manufacturers in the automotive sector to carry out these developments. The developments in this area allow us to monitor the O&M actions of specific components within an installation, thus enabling guided and collaborative methods to carry out the planning of these tasks.

In the development of digital twins, we start by compiling information about the assets to be virtualised to subsequently carry out 3D scans of the target installations.

METHODOLOGY

The virtualisation is carried out using 3D scanning and spatial capture tools like Autodesk ReCap, Reality Capture and visualisation tools like Twinmotion, Autodesk Revit or graphics engines designed for the film and video game industries.

In the development of digital twins, we start by compiling information about the assets to be virtualised to subsequently carry out 3D scans of the target installations. The use of drawings and other documentation that allows detailing the replicas is also a common practice in these scenarios. After conducting a preliminary study of the installation, we then add sensors to the installation to obtain data in real time about its operation and implement them in the digital twin. By analysing the collected data, studies are conducted of the state and performance as required. Once the geometries of the installation are replicated in a virtual environment, it operation is simulated based on the data received in real time originating from the replicated assets.

SOLUTE has 3D laser and image scanning devices as well as virtual and augmented reality viewers to guarantee accurate visualisations in the virtualisation in addition to having workstations for processing of point clouds and rendering of 3D models.

These described tasks make up an interactive application with access to the digital twin, offering the possibility of knowing its state, generate performance reports and plan actions as well as simulate improvements without stopping the operation of the real installations.

Wind

Intelligent building and smart control of energy consumption

Improvement in the efficiency of buildings to implement automation strategies with the aim of carrying out an intelligent and efficient energy demand management.

Software

Web/ App development

Web / app development is the interface that allows the user to interact with a platform by communicating with the backend, which is the part that manages and processes the provided information to return the requested results through the app.