Life extension evaluation of towers and foundations

BACKGROUND

The life extension evaluation of certain wind turbine components is very much demanded at the moment as many of the existing turbines are nearing the service life expiration date they were designed for.

SOLUTE has a team of structural engineers that carry out an evaluation of the conditions under which the turbine is operating and applies them to finite elements models for conducting a subsequent fatigue analysis.

During the design phase of a wind turbine, the components are designed for a specific service life. In the case of foundations and towers, this service life is normally around 20 years. The owners of large parks are interested in extending the service life of these turbines as much as possible in order to obtain a greater performance from the installed wind turbines. In this sector, SOLUTE presents itself as a solution for conducting life extension evaluations.

RESULTS

Via the conducted fatigue analysis, we will determine if the wind turbine components are able to withstand the loads obtained for a specific additional service life. Based on the scope of the evaluation, it could simply be focused on the validity of the structure or on checking the validity and the proposal of solutions in case of failure. In any case, after the analysis, a report of results will be drafted with the applicable conclusions.

EXPERIENCE

The main customers that are interested in these types of evaluations are component manufacturers, wind park developers, public administrations and private companies.

Since 2017 SOLUTE has been conducting life extension evaluations of towers and foundations for different interest groups, such as park owners and builders.

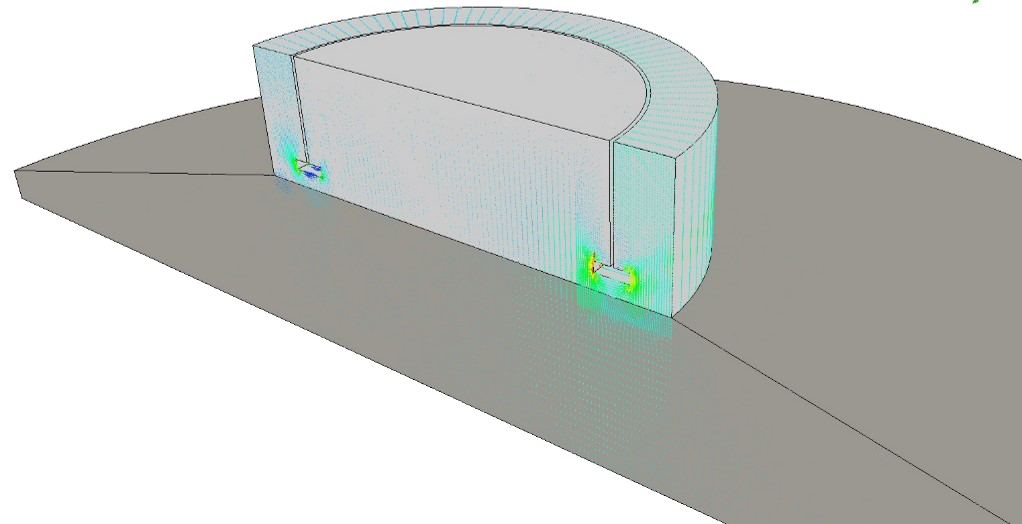

Finite elements models (FEMs) are used that resemble reality, such as ANSYS or SAP2000, which allow inserting equivalent damage loads originating from the inputs in order to obtain the stresses to which each element being evaluated is subjected to.

METHODOLOGY

The aim of a life extension evaluation is to evaluate the remaining life with fatigue of each component in accordance with current regulation.

The methodology that is used is focused on evaluating the inputs available on the wind turbine, which entails analysing the equivalent fatigue loads of the turbine according to the winds it has been subjected to during its service life, existing conditions on the ground, condition of the materials of each component, etc.

For this, finite elements models (FEMs) are used that resemble reality, such as ANSYS or SAP2000, which allow inserting equivalent damage loads originating from the inputs in order to obtain the stresses to which each element being evaluated is subjected to.

Finally, we evaluate the fatigue damage of each component by analysing the stresses that are produced and draft a final report with the customer’s requirements and propose solutions via drawings and other necessary documentation.

The regulation that is used for fatigue analysis will follow the material and load requirements set out in IEC61400-1 and IEC61400-6, Eurocodes, Structural Code, DNVGL-ST-0126, DNVGL-ST-0262, and Model 2010 Code.

Solar

Structural systems design for PV plants

Structural systems design phase analysis for calculating the generation of solar energy using photovoltaic panels in demanding environments such as with winds or earthquakes.

Wind

Energy and weather forecast for renewable operators

Weather and energy forecast service through the training of artificial intelligence algorithms.